Previous

Next

State-of-the-art Technology

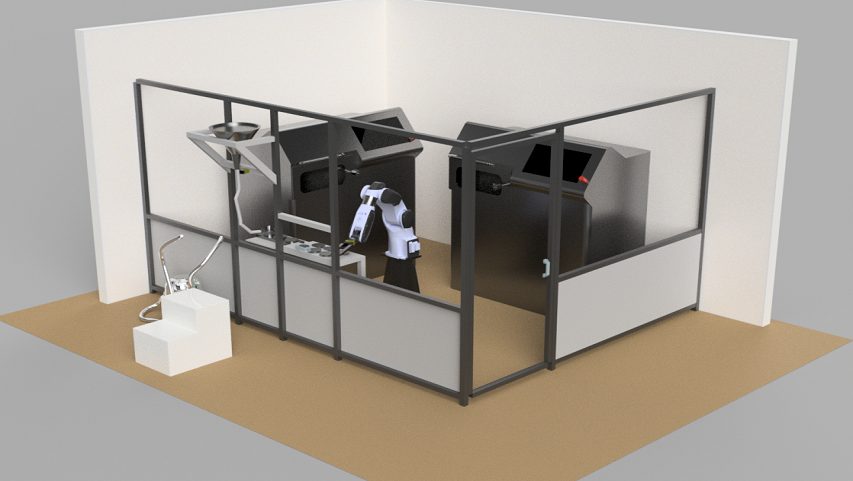

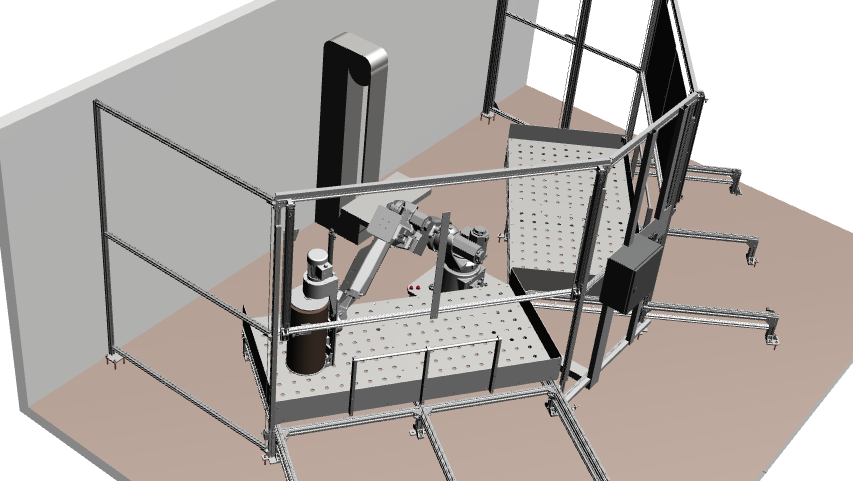

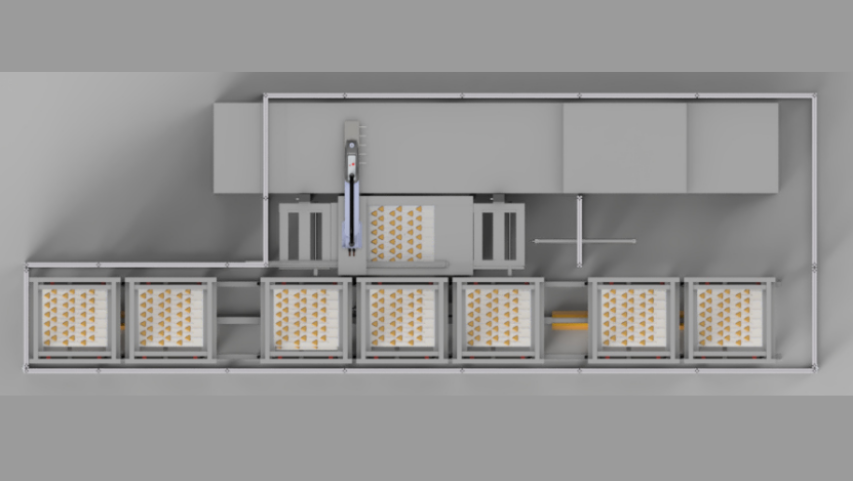

Our machining systems are complete systems suitable for the implementation of molding or material removal manufacturing processes. They can be expanded with additional functions due to their modular design. Upon request they include:

- an automatic palletizing system for continuous material flow, with which a high productivity increase can be achieved, ,

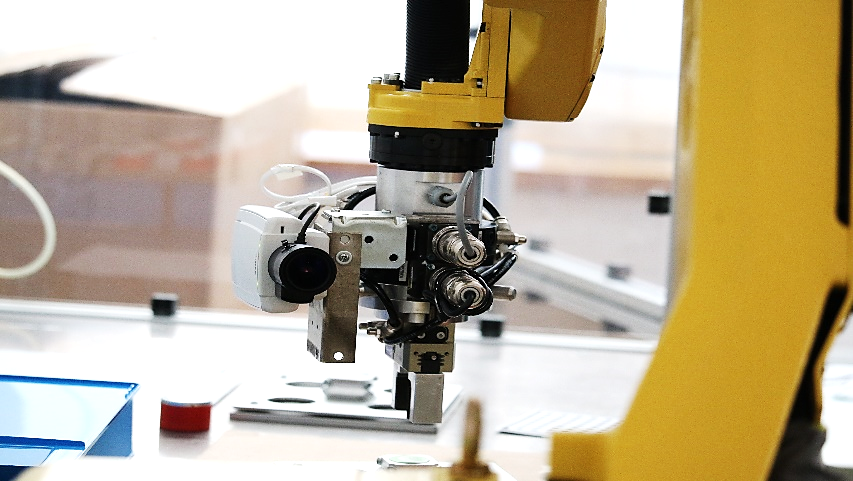

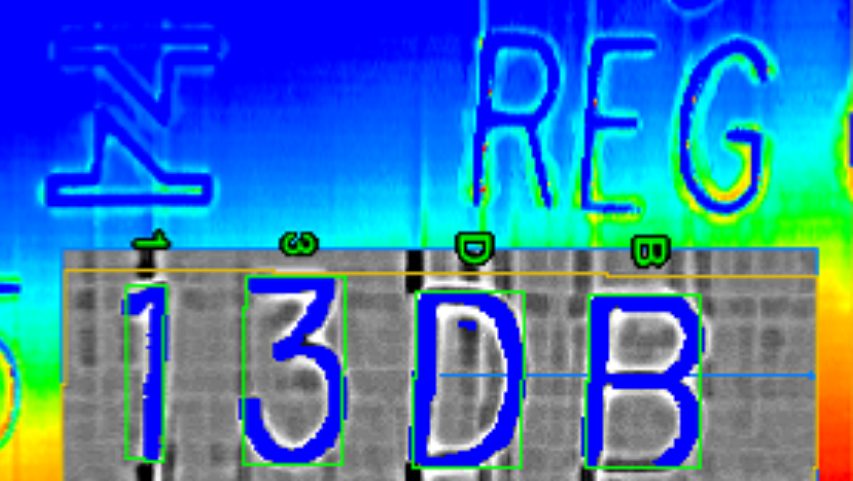

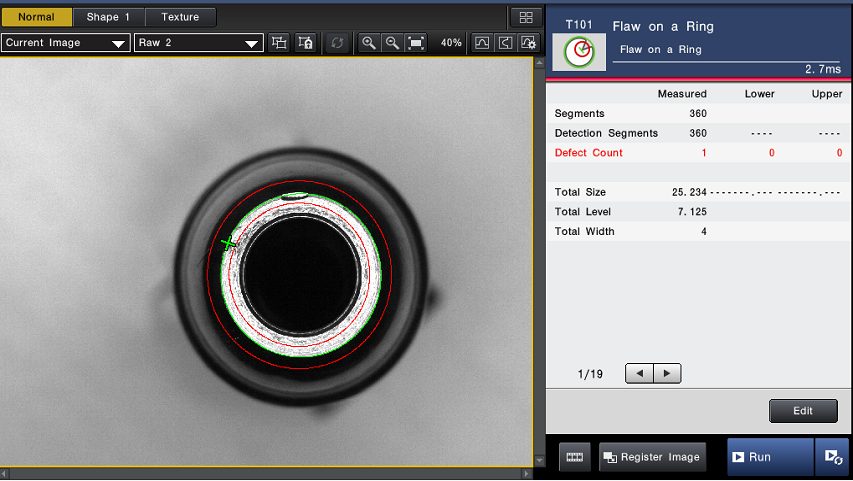

- a measuring system that monitors the results of technological processes,

- marking technology that allows the tracking of semi-finished and finished products throughout the manufacturing process.

Our flexible production stations operate reliably with short cycle times, for both large and small series production.

Our service is available to support scheduled maintenance.