Previous

Next

Speed and accuracy

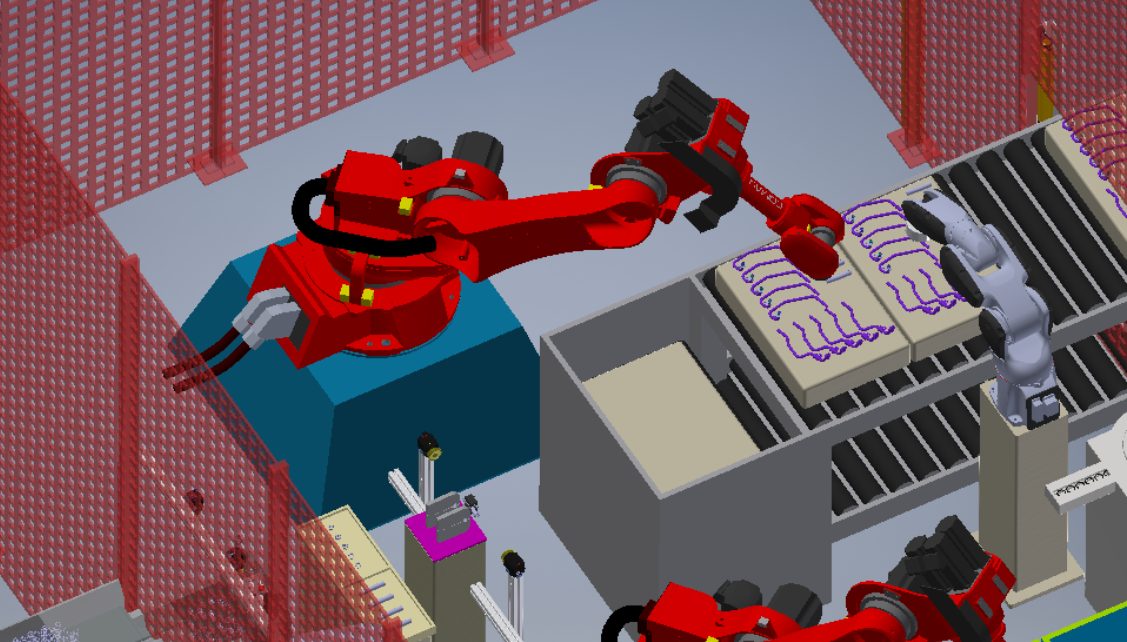

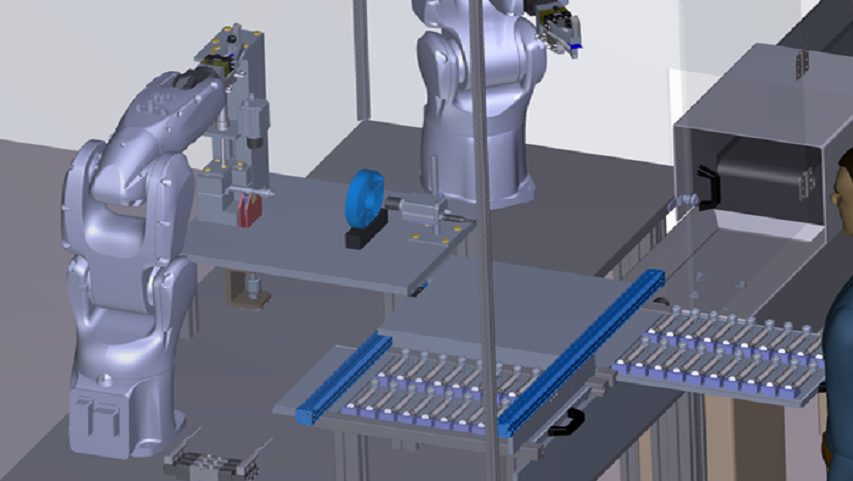

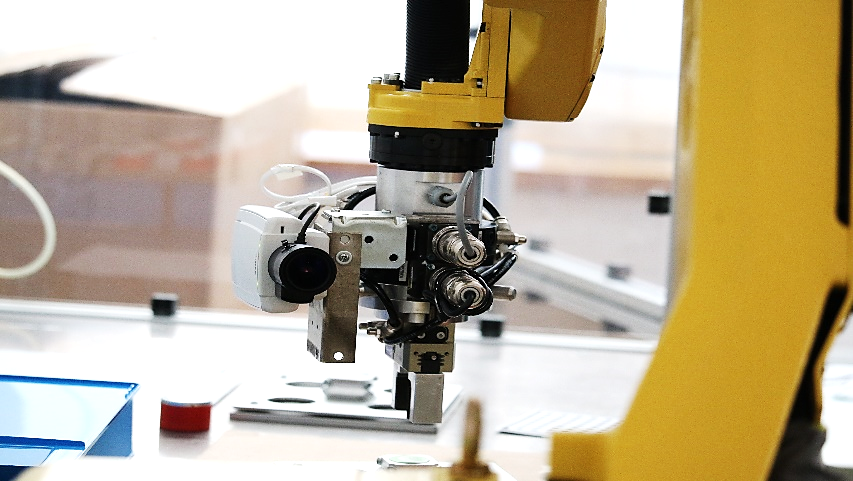

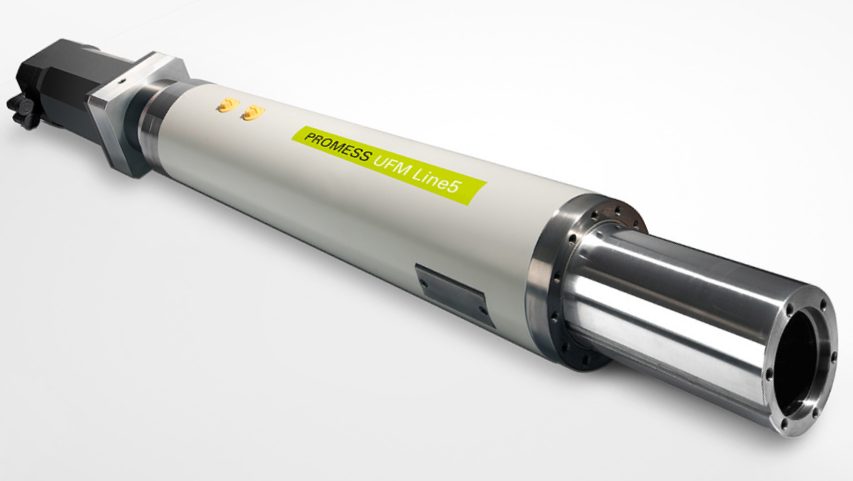

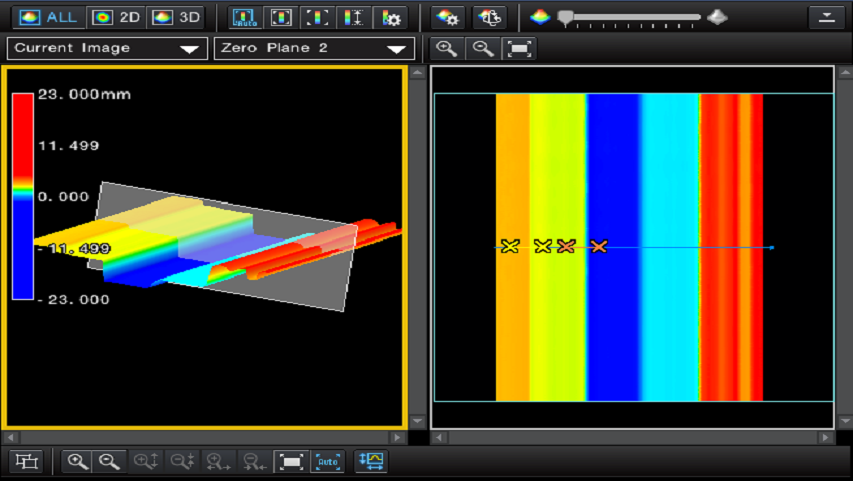

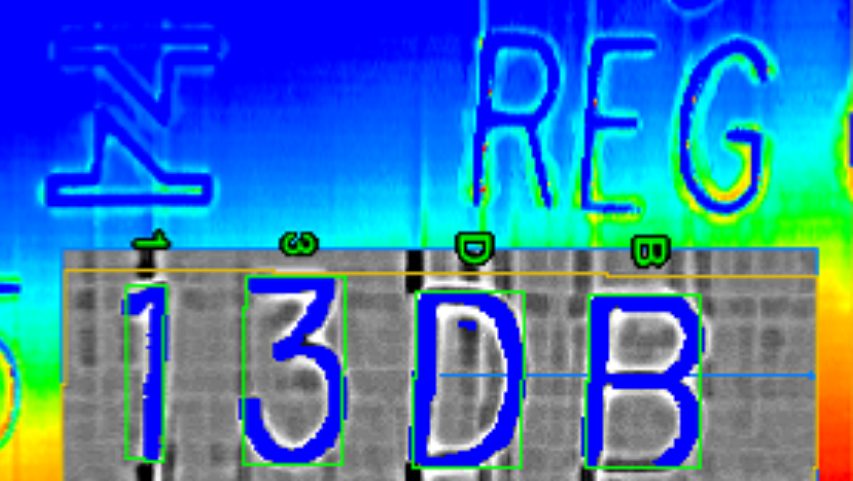

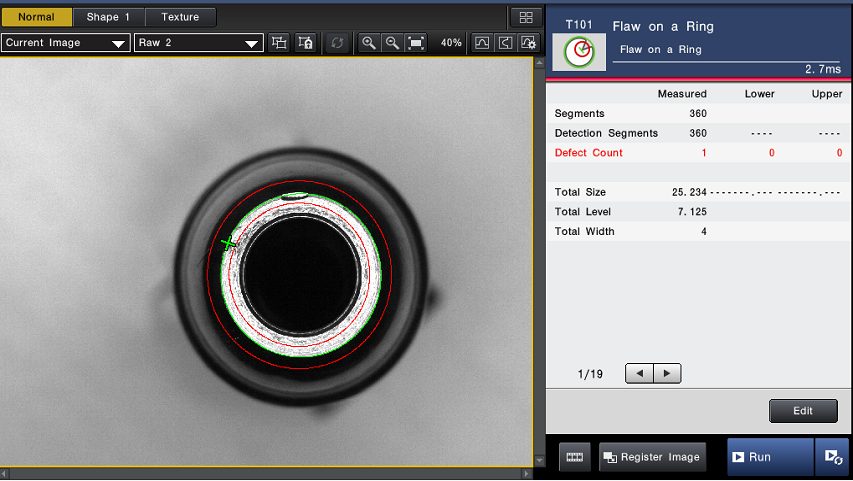

Our assembly systems are the results of our own research and development they are capable of realizing a fully automated assembly of both flexible and rigid components with high precision. As a result of their modular design they can be expanded with additional functions. They are available with an automated palletizing system which facilitates the continuous flow of materials, resulting in increased productivity. Upon request they can include servo presses and torque sensor systems, with which assembly can be carried out with precision and high quality. We build our assembly lines with PROMESS servo presses and torque sensors, of which we are the official Hungarian service.